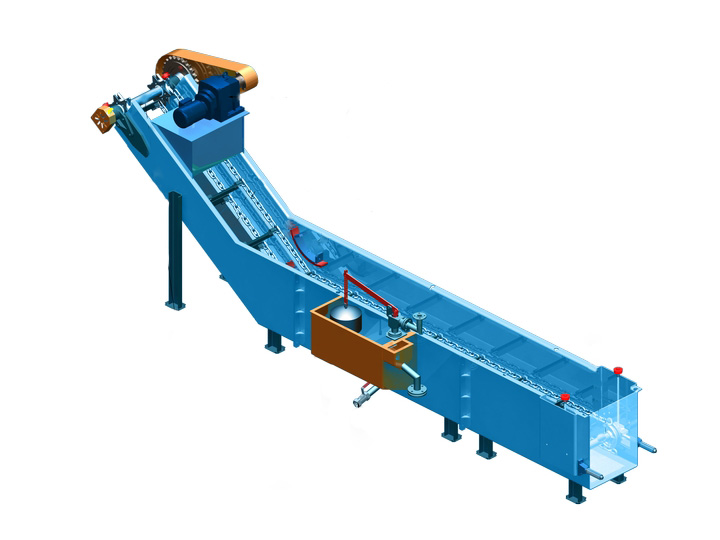

We have been making OZDW-type scraper conveyors for decades. An OZDW conveyor is a single-trough unit. Slag and ash are removed from the bottom of the trough. OZDW-type scraper conveyors are modern and extremely efficient solutions for use in the power and heat generation industries. All our OZDW-type conveyors can be fabricated according to customer-supplied documentation. However, our team of experienced designers and structural engineers is available to do the design work for you. We offer both OZGW-type and PPZ-type scraper conveyors.

The main advantages of OZDW-type scraper conveyors made by ZUK are:

high durability and

trouble-free operation.

If you are interested in our OZDW-type scraper conveyors, contact us. Why not visit our website for technical catalogues with details about the technical specifications of our products?

How are ZUK’s OZDW-type scraper conveyors made?

OZDW-type scraper conveyors are available with the following standard trough widths: 350 mm, 570 mm, 770 mm or 1000 mm. The trough length range is 3-25 metres. The size of the conveyor will normally depend on the boiler type and the place of installation of all the other conveying equipment.

What are the parts of an OZDW scraper conveyor? They are:

a slag removal trough,

a front shaft,

a rear shaft,

a motor drive,

a scraping belt,

sliding plates or a basalt panel,

replaceable slides or a guide roller,

a float compartment, and

a discharge valve.

The dimensions of the conveyor, such as the total length, the width of the trough(s) or the height of the drive shaft, can be discussed and agreed with the slag removal system designer or directly with the user.